Effective Industrial Filtration Solutions

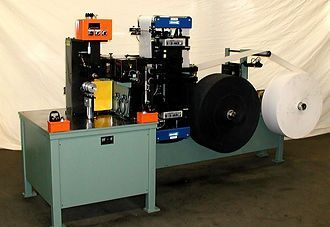

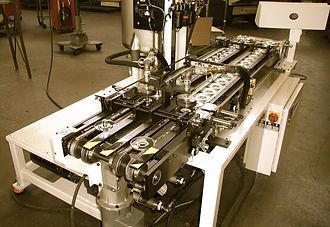

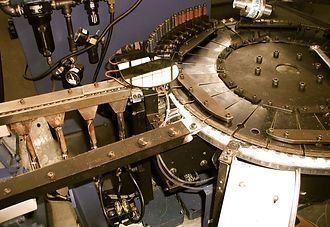

Our industrial filtration machinery is designed to handle high-demand production environments with precision, reliability, and efficiency. Engineered using robust materials and cutting-edge filtration technology, each unit is customized to meet your industry's unique needs. Reduce downtime, improve product quality, and maintain operational compliance with filtration systems you can depend on.

Custom Machinery for Unique Manufacturing Challenges

When off-the-shelf solutions fall short, our special machinery delivers. From dispensing systems and ultrasonic welding to thermal heat staking and complex assemblies, our custom-built machines are developed to align perfectly with your production goals. Every design is backed by decades of engineering expertise and a commitment to solving your most specific manufacturing challenges.

Contact us

Fill out the form below to get in touch with us. We look forward to hearing from you!